The French Phosphate Company operated two

train sets of mining equipment here. The two 0-4-4 narrow gauge locomotives

were built by Porter as c/ns 1446 and 1587. C/n 1446 was built in

January of 1893 and 1587 was built in March of 1895. Both locomotives were

built with 7x12 inch cylinders and were 23.75 inch gauge. The official

name of the company was the " Cie des Phosphates de Franco". Note that

there were two different styles of ore cars used. Don Hensley Collection.

Phosphate was in great demand in Europe following it's discovery in Florida. At that time Europe had very little resources at all in phosphate. Later on the mineral would be discovered in French and British colonies through out the world. But in the late 1880's and to the beginning of the First World War, Florida was the main source of phosphate for the Europeans. Both France and Great Britain maintain mining companies in Florida. The French Phosphate Company first mined one of the rarest forms of North Florida phosphate called plate rock. This was located near Citra, Florida near Ocala. The French even operated a 60 cm (23-7/8") gauge railroad at Citra, purchasing a locomotive from Porters. Around 1894 this mine finally was running out of ore and a replacement was needed to keep production up. The French decided to enter the Luraville Phosphate area by buying up many of the independent mines in the area.

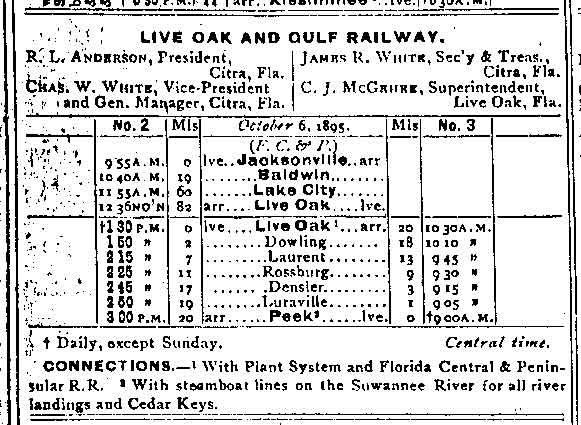

However a railroad was needed and as the LOL&DBRR was stalled, the French contacted their American business agents, Charles & James White of New York, NY, who was in Citra, managing the French properties. Another business partner was Robert L. Anderson of Ocala who also was invited in. Together these three men incorporated the Live Oak & Gulf Railway Company on January 4, 1895 with $5,000 in capital stock. Anderson was elected president, Charles White became vice-president, while James White took over the duties of secretary and treasurer. At the same time they took over the roadbed and assets of the Live Oak, Luraville & Deadman's Bay Railroad, but not its charter. Originally Robert Anderson had 5 shares, Charles White had 10, and James White had 35. But on March 5, 1895 the capital was increased to $150,000 though only the $5,000 was issued at this time. Also W.C. Remick and Thomas McIntosh of the LOL&DBRR was brought on board and issued 5 shares a piece by transferring 5 shares each from Charles and James White's shares. Then a mortgage account was started with the New York Security and Trust Co. of New York, NY.

Construction began in February at a fast pace, one mile of track had been laid by March 1, 1895. James R. Morehead, listed as Roadmaster, supervised the construction. By May 15, 1895, the entire 12 miles of track from the end of Dowling's Log Railroad to the Suwannee River at Peek, 2 miles west of Luraville had been finished. $100,000 worth of bonds were issued by the mortgage company. Even Dowling's Log Road had been reconstructed, so there were 19 miles of new track laid. But the Live Oak & Gulf still needed to purchase Dowling's 7 miles of grade. The mortgage did not include the purchase of this property, so the LO&G went to the Florida Central & Peninsular with empty pockets and open hands. After signing a preferred connection agreement and hiring a FC&P man as a General Manager to operate the company, the big road loaned $5,000 for the down payment of Dowling's Log Road with the track as collateral.

Operations began on May 1st with Charles McGehee of Live Oak as General Manager. McGehee was also the FC&P station agent for Live Oak and would also be involved in many business ventures through out North Florida, from owning a machine shop/locomotive rental business to operating a large sawmill. The Live Oak & Gulf owned two locomotives, more than likely Charles Dowling's old locomotives. The engine house was on the mill property in Live Oak. The company also owned one passenger car with a matching baggage car. Two flat cars rounded out the roster. Operations were good for the first year of business, over 9,000 tons of phosphate was hauled for a revenue of $11,388 and they earned $1,854 hauling general freight and $1,036 carrying passengers. Expenses amounted to only $6,080 which left plenty for paying the interest on their debt. The nearby Suwannee River Railroad was by now abandoned, though it would live on in maps and schemes for the next 10 years.

The French Phosphate Company was also booming, it had moved their 60 cm gauge railroad from Citra, and purchased a new locomotive from Porter and some new ore cars. A two mile branch line was built from Densler Jct. (just east of Luraville) to the Phosphate Mills. Now the Luraville phosphate operations were served by two complete narrow gauge train sets hauling the hand dug rock from the pit to the washing and drying mill. Now here is how they mined phosphate back in the good old days. First a hollow pipe is hand driven into the ground for soil samples. Samples are then analyzed for their content of phosphate and their content of iron. Iron in this case is bad, if the sample is over 3 percent the phosphate can not be used. Also the phosphate percentage had to be over 75 percent, though phosphate in this area was usually a rich ore, averaging around 90 percent. But the iron was the bane of this operation in Suwanne County as many times it would be over the 3 percent level, up to 7 or 8 percent, which ruined the phosphate as a fertilizer. Once a large body of good phosphate was discovered, a pit would be dug by shovel and pick, usually by local African Americans from Live Oak. The removal of this overburden as it was called was help out by the narrow gauge tram roads, which could haul it out. Once the pit was dug down to the phosphate deposit, which was in the form of large boulders laying over the native limestone, the boulders would be hand picked and loaded onto the ore cars and hauled to the mill. The mill would then crush the rock to pebble size and then the pebbles would be laid onto a bed of wood, in an open shed, the wood bed is lit and the ore was dried to remove the moisture for shipping. Once dried it would be loaded onto box cars and hauled to Jacksonville for loading onto steamships for France.

The 1890's method of digging a pit. Here is

the first step of clearing the land, using shovels and mules pulling scrappers.

Don Hensley Collection.

As we can see the Live Oak & Gulf was built to haul phosphate which it did very well during its first year of operation in 1895. Assuming an average of 20 tons per car, over 450 carloads of ore were hauled out to Live Oak. A mixed train and a phosphate extra was run daily during this period. 1896 was even better, hauling out 10,800 tons of ore in 540 cars. One of the locomotives was scrapped or sold that year, but they leased a locomotive from William E. Boone of Jacksonville, Fl to help take up the slack. The only known photo of a LO&G train has this W.E. Boone locomotive up front. W.E. Boone was an ex-master mechanic of the Florida Central & Peninsular (SAL) and had his shops at their yards in Jacksonville. He would buy old motive power from his old employers as well as many of the other roads nearby, like the Southern, Central of Georgia and the Savanah Florida & Western (ACL). He was partial to Rogers, but he also bought other cast offs as well. The photo of the LO&G locomotive appears to be an old Danforth Cooke engine. W.E. Boone locomotives are easy to identify, they always had his initials ( W.E.B.) under the cab and they were numbered from 90 to 135. He leased and sold these old engines through out Northern Florida and Southern Georgia to logging and mining concerns as well as to shortlines.